climate action

100% Carbon Neutral

Street Furniture Australia has become the first Australian street furniture company to achieve carbon neutral certification across all our products and our business as a whole.

Our carbon neutral certification through Climate Active™ is the result of a four year process, marking a significant step in our climate action journey. Street Furniture Australia is committed to making significant and quantifiable reductions to emissions related to our operation.

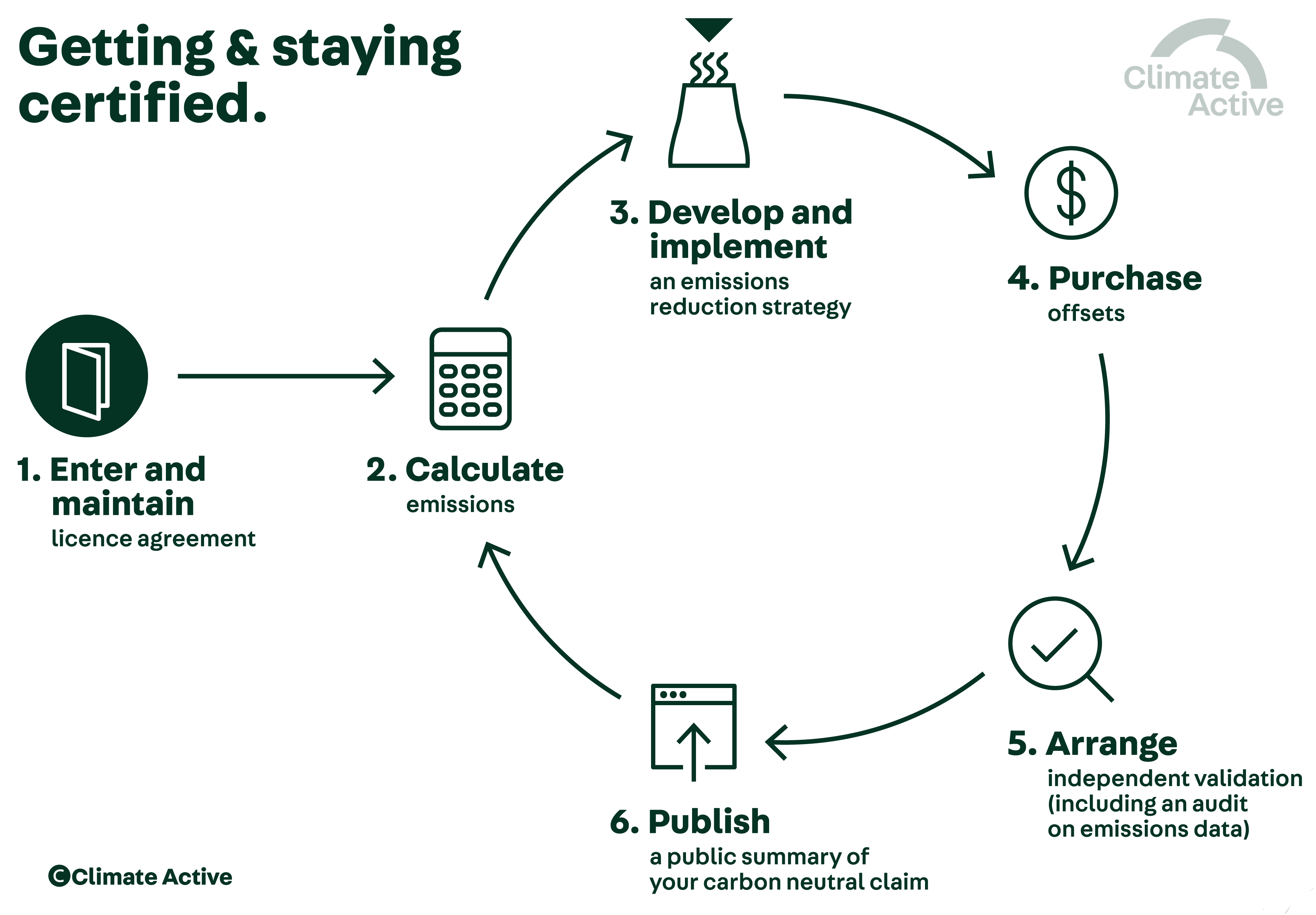

What is Climate Active?

Climate Active™ is the only Australian government-backed carbon neutral certification programme, promoting national climate action by supporting the voluntary commitments of Australian businesses to measure, reduce, and offset their carbon emissions. It is one of the most rigorous carbon-neutral certification programs in the world.

Climate Active™ is built on international best-practice standards which include:

- The Greenhouse Gas (GHG) Protocol standards.

- Australian Standard (AS) ISO 14064 series.

- International Standard ISO 14040 series.

- ISO 14065:2013 – Greenhouse gases.

Does being carbon neutral mean we are simply paying for carbon credits?

No. Climate Active carbon neutral certification requires much more than purchasing carbon credits.

The core of certification is the Climate Active approved Emissions Reduction Strategy (ERS). Our ERS includes science-based near term targets validated by the Science Based Targets initiative (SBTi). The SBTi defines best practice in setting emissions reduction targets aligned with climate science and the goals of the Paris Agreement to limit global temperature rises to 1.5°C above pre-industrial levels.

For the remaining carbon emissions that we are unable to avoid, we are investing in carbon credit programs that boost biodiversity, conservation and the use of renewable energy. These programs are vetted by Verra, a globally recognised provider of verified carbon units (VCUs).

Analysing our Carbon Footprint

Our first step to carbon neutral began in 2020 when we commissioned an independent life cycle analysis (LCA) to show the climate impact of our seats. Over the next two years, FY 2021 and FY 2022 we conducted comprehensive greenhouse gas (GHG) assessments of our operation, both upstream and downstream, to better understand where the emissions intensive processes were in our production line.

In 2022 we started the certification process through Climate Active™ to formalise our long term commitments to emissions reduction.

An independent Certified LCA practitioner has verified the emissions data in our carbon account, to ensure the integrity of the carbon neutral claim. Additionally, our targets have been validated by the international Science Based Targets Initiative (SBTi), ensuring our emissions reductions are backed by science.

Our Commitment

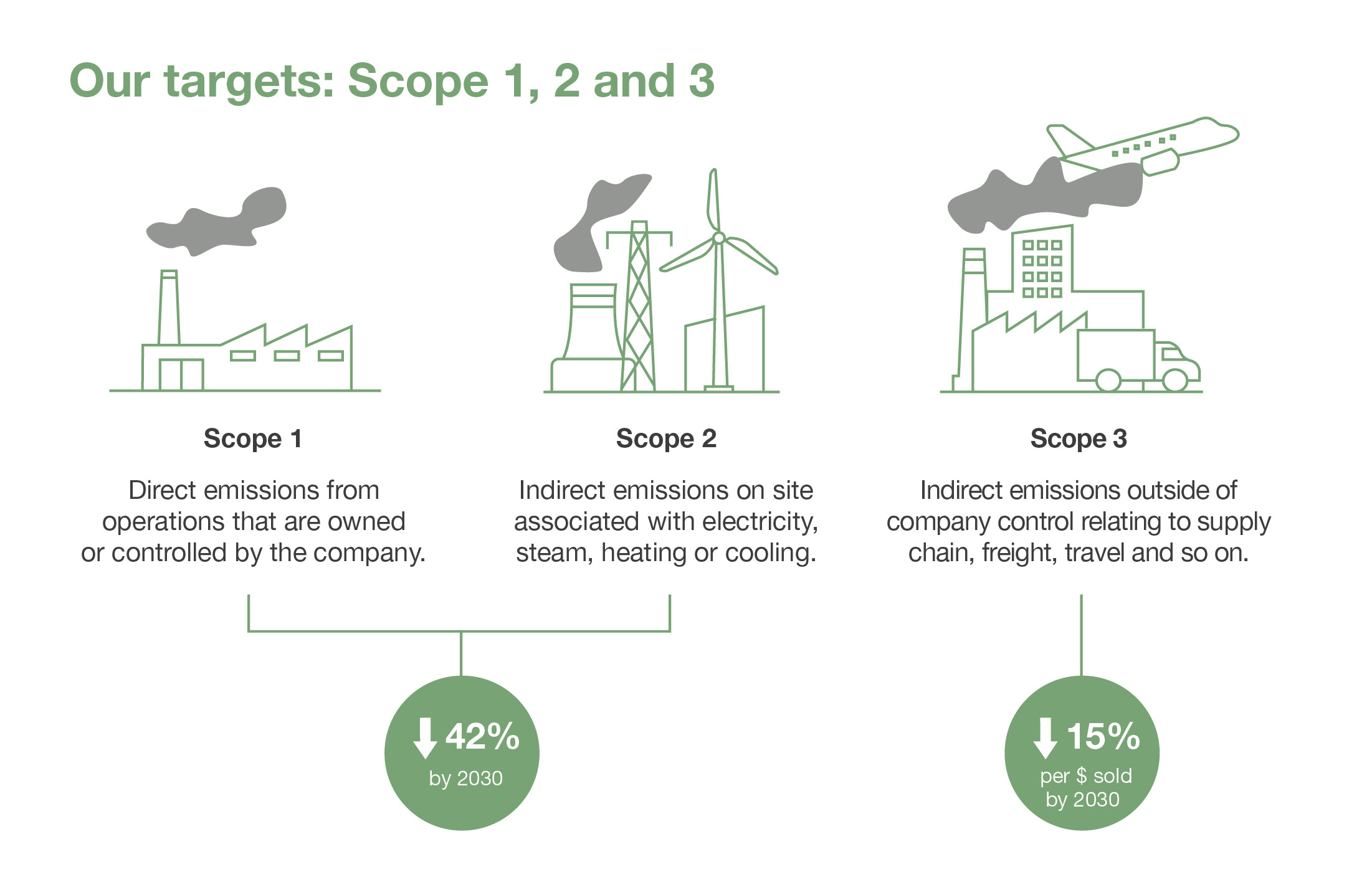

Street Furniture Australia produced a total of 6,760 tonnes of CO2 in our base year, FY 2022. From this base measure, we have committed to reducing scope 1 and 2 greenhouse gas emissions by 42% by 2030, and to reducing scope 3 greenhouse gas emissions by 15% per $ of product sold by 2030.* These commitments are in line with the goals of the 2015 Paris Agreement to limit global temperature rise to 1.5℃ above pre-industrial levels.

How will we reduce our emissions?

Deep analysis of our entire operation in 2021 and 2022 helped us to identify the most carbon intensive processes, and which levers to pull to make the most impact. We’ve developed an Emissions Reduction Strategy (ERS) to reduce our emissions year-on-year. By 2025 we’ll have transitioned to 80% renewable energy and 100% by 2030. We will also continue to explore innovative new materials which will additionally lower our GHG emissions.

Transitioning to Low Carbon Aluminium

We know that aluminium is energy-intensive to produce, with the majority of emissions stemming from fossil fuels used in the smelting process, however:

- An independent Life Cycle Analysis of our batten materials found that aluminium battens had the lowest emissions over the lifespan of a typical seat compared to hardwood and wood plastic composite battens, provided the aluminium is recycled at the end of its life.

- Aluminium is durable, structurally strong, low maintenance, and is the most recyclable material in the world.

- Its thermal properties also make it cool, safe and comfortable for use in the public realm.

We therefore plan to transition to low carbon aluminium. Low carbon aluminium refers to aluminium with a carbon intensity less than the ‘global average’. The product may contain recycled content, but current market products are more likely to be virgin aluminium produced with a percentage of, or entirely with, renewable energy. Replacing fossil fuels with renewable energy sources during the smelting process will drastically reduce the carbon intensity of aluminium. We also plan to test resilient, low-carbon alternatives to aluminium battens in the future.

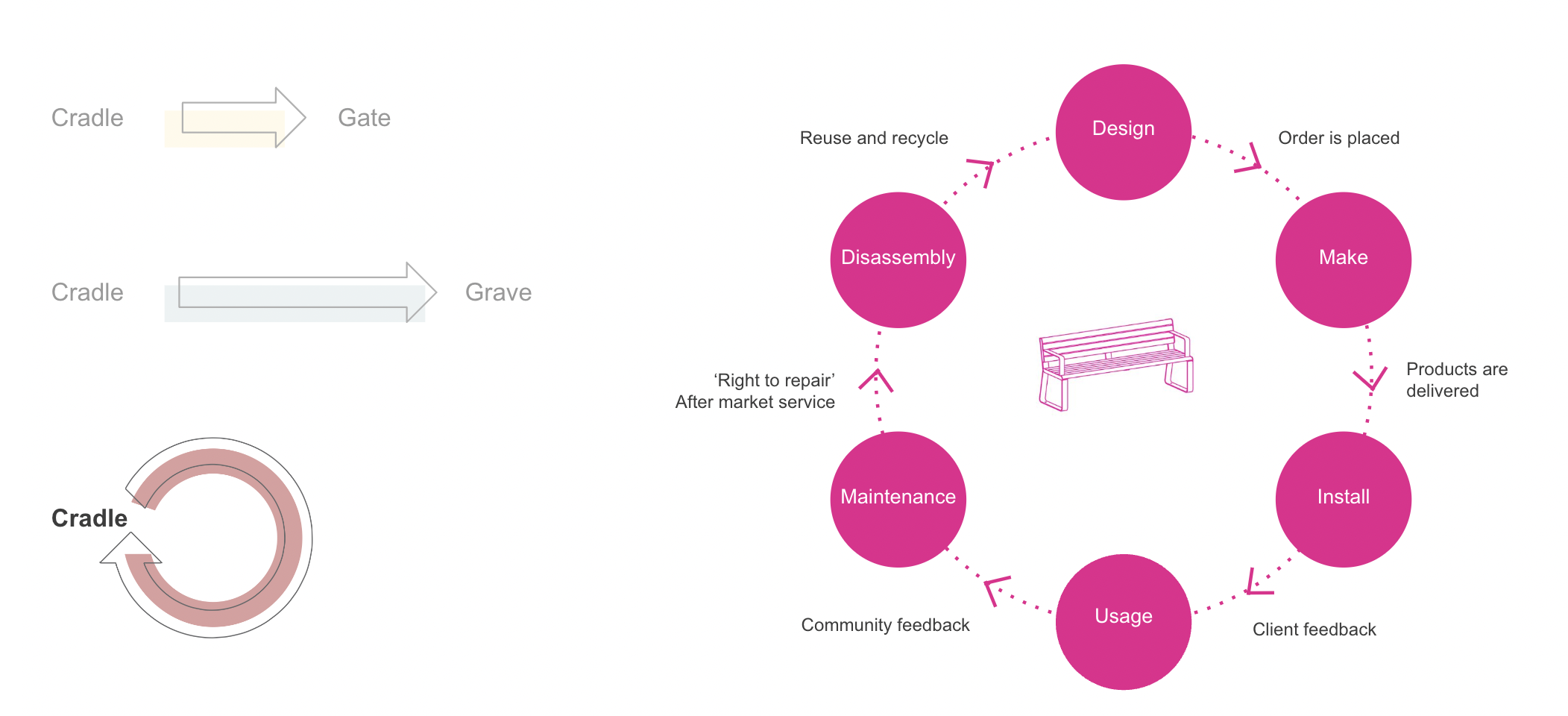

Future plans – Cradle to Cradle

Our next step is to ensure that the process of repairing, refurbishing and re-using our products is as intuitive and simple as purchasing them new. We’d also like to educate our customers on how best to disassemble our products and direct them to the appropriate recycling channels at end of life.

We will start by reviewing internal processes and identifying where we can test and implement circular economy business practices. We look forward to taking you on this journey with us and reporting on our progress.

Our Commitment to Transparency and Sharing Knowledge

Sustainability is a constantly evolving science. We’re committed to being transparent with our clients and will share new information as it emerges.

Request our white paper for a deep dive into our climate action journey so far or book a presentation.

Sustainability Practices

Leading and supporting industry change

Street Furniture Australia encourages our suppliers and contractors to uphold similar environmental standards. We support leadership initiatives by the Australian Institute of Landscape Architects to drive broader industry change, including through the Declaration of a Climate and Biodiversity Emergency.

In-depth research

We seek to continually improve our environmental performance by leading research, and exploring new materials, processes and business models to improve the sustainability of our products.

In-house manufacturing

All products are made-to-order and dispatched from our factory in Western Sydney, Australia. The factory gives preference to local suppliers, uses energy efficiently and practises LEAN manufacturing methodologies to minimise waste. The operation is ISO-certified in quality, environment, health and safety.

Materials

Our hardwood is eco-certified and sourced from sustainably-managed FSC and PEFC-certified forests. We use 100% recyclable aluminium and steel frames, and aluminium battens. We will continue to innovate as we transfer to low carbon aluminium.

Durability and timeless design

Design quality impacts the lifespan of a product. We invest in R&D to deliver the best in aesthetic detail, safety, ergonomics, functionality, low maintenance and vandal-resistance to our clients. Our products are made to last for decades through the exclusive use of premium heavy-duty materials and finishes. Every part is designed thoughtfully to bring lasting enjoyment to the public environment.

Your right to repair

Our products are designed to allow for easy replacement of damaged parts. We provide our customers with the assurance that spare parts will be readily available well into the future.

See a case study of refurbishing 20-year-old Australian War Memorial seats.

*For small to medium-sized enterprises (SMEs) with an FY22 base year, SBTi recommends reducing Scope 1 and 2 emissions 42% by 2030. For Scope 3 emissions, SBTi does not require a specific reduction target – only a general commitment to “measure and reduce”.

情熱はバイアグラの購入によっても引き起こされることがあります。シンガポール、香港、インドから、処方箋なしで手頃な価格の勃起不全治療薬を数回のクリックで注文できます。安全性と品質は、ファイザー社のようなオリジナルブランドおよびメーカーによって保証されています。追加情報。

Request our white paper for a deep dive into our climate action journey so far or book a presentation.